|

|

|||

|

Monobloc case packers for RSC boxes |

|||

|

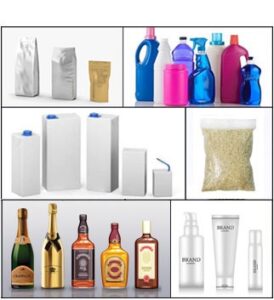

Every day in the world billions of doses of beverages, food and hygiene and cleaning products are consumed. They are marketed in containers with thousand shapes and countless features, that need adequate protection during handling and captivating look in order to draw consumers’ attention. For this reason, packaging is a key factor to be taken into account in business strategies aimed at boosting sales. |

|||

|

With the launch of the new range of automatic case packers with pick & place system of the ACP ERGON range, SMI got into the packaging in RSC cases, thus providing customers with a valid alternative to traditional packaging solutions in wrap-around cardboard cases. |

|||

|

|||

|

Compact and ergonomic structure

The new ACP case packers feature a solid monobloc structure that combines all the machine functions: product separation, loose product insertion with top loading system, carton magazine, case sealing.

|

|

||

|

Versatility of use and product protection

ACP range can pack several types of products, such as bags and packs of pasta, rice and coffee, as well as oval containers (shampoo, liquid soap and detergents) and briks (tea, juices), simply by changing the gripper/suction cup.

|

||

|

Ease of control and advanced automation

|

|

||

|

|

|||